Blog

Procurement Supplier Management

By Mark Hubbard |

Procurement Supplier Management has been a challenging area to deal with for a whole series of reasons – it is worth having a close look at some of the issues and opportunities surrounding the subject area.

Which sectors focus on Procurement Supplier Management?

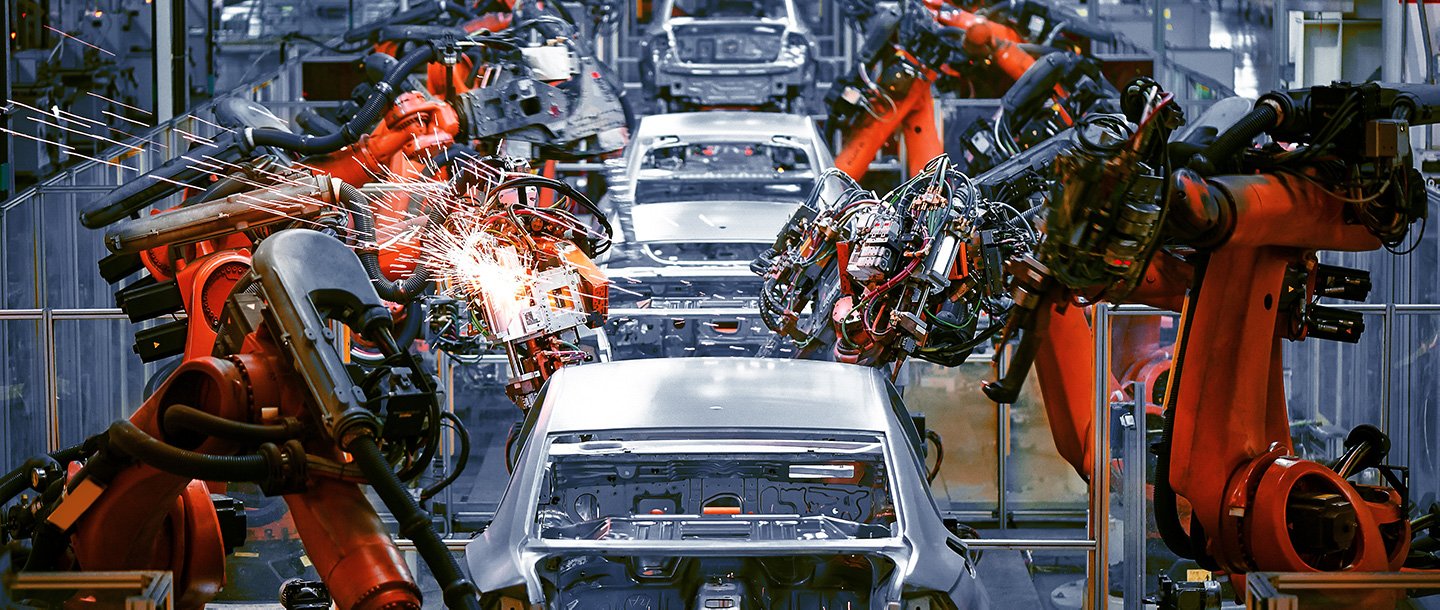

As a starting point, it is worth reflecting that, in general, procurement supplier management SRM, gets far less attention within organisations than it deserves. This isn’t true everywhere; some sectors put considerable effort into supplier management and lean heavily on their suppliers to maximise the value they can achieve from their whole supply chain. The leaders in this space are, arguably, the automotive sector. They have been working this way for tens of years; this entire approach is likely to be second nature to those businesses.

Addressing procurement supplier management is thought of as only something for the automotive sector because there is something about the automotive supply chain that makes it possible. Having worked in that space, I would suggest that this is not a correct assumption. The carmakers put a vast amount of effort into this space and get the returns from it that make it worthwhile. Most other sectors have no real visibility of the depth of effort made to get to that advantage, so they often choose to do little or nothing.

The Supplier Meeting.

A second point here is recognising that many of the standard approaches to supplier management seem to have ‘the supplier meeting’ as the peak of the possible activity between two organisations. As ever, excellent communications help, but a quarterly meeting is unlikely to be the huge delivery mechanism for the value that some appear to believe it is.

Instead, and as with category management, a structured approach that identifies the best way for two organisations to create value together is where we should focus our attention. It needs creativity and thought at the front end and ruthless management of delivery projects at the back end to make sure that the desired value is both evident and realised.

How do we get to some of this magical value? We need to recognise that not all suppliers are equal and we have a finite amount of resource available.

Focus on which suppliers to engage with.

We need to focus on which suppliers we need to engage with and keep this under regular review. Having a mechanism that allows you to review the key suppliers to spend resource on is critical to the whole process. Without it, time can be spent on futile programs that deliver nothing.

We also need to know why we want to engage with suppliers by focusing on our own organisation’s strategic intent and ensuring that we are working most closely with the suppliers who deliver in alignment with that direction. Remember, this may not be the one we spend the most money with

There’s another essential element here; the supplier must be willing to join in with the supplier relationship management activity. If they are not interested or perceive that there is no benefit for them, they are less likely to be willing. As such, we may need to do some up-front work to establish both what we need to get out of the approach and spend time understanding what they get out of it.

What does good performance look like in Procurement Supplier Management?

Another element that often proves troublesome is knowledge; what does good performance look like for SRM, and can we measure that effectively? Programs often fall apart because there is no way to look at performance in any meaningful way, in any areas that matter.

However, we need to consider the available upside if we manage to get through all of the perceived barriers. Working effectively with suppliers can deliver whole percentage points of improvement in various areas, and the best programs offer far more.

Better flexibility, resource management, access to innovation, supply chain robustness, ideas, support, training, quality of service and more are examples found in the past. When done well, deliver value in the range of multiples of the program needed to access the value.

Unfortunately, the hard evidence that defines these outcomes is often difficult to come by. We see enough to suggest that well-managed programs deliver excellent results, and poorly designed and implemented programs do not.

Many businesses spend around half their sales dollars with suppliers. Managing the value created from that supply chain for maximum potential seems to be a good way of creating more success for our businesses.

Getting great at Supplier Management is a worthwhile investment.

About Mark Hubbard

Director

30+ years experience in procurement and supplier management, in line and consulting roles

Previous employment: Positive Purchasing Ltd, SITA,

QP Group, BMW, SWWS, Rover

Education: BSc in Engineering Metallurgy, MBA University of Plymouth

CIPS: Current Member

Further Reading

Blog

A practical supplier management programme – Three key building blocks

17/04/2020

Read More

Case study

At AstraZeneca the foundations of category management are built on stakeholder engagement

07/11/2023

Read More

Case study

Mark Smith interview – A lean category management model is at the heart of procurement at bp

08/02/2024

Read More